MANUFACTURING

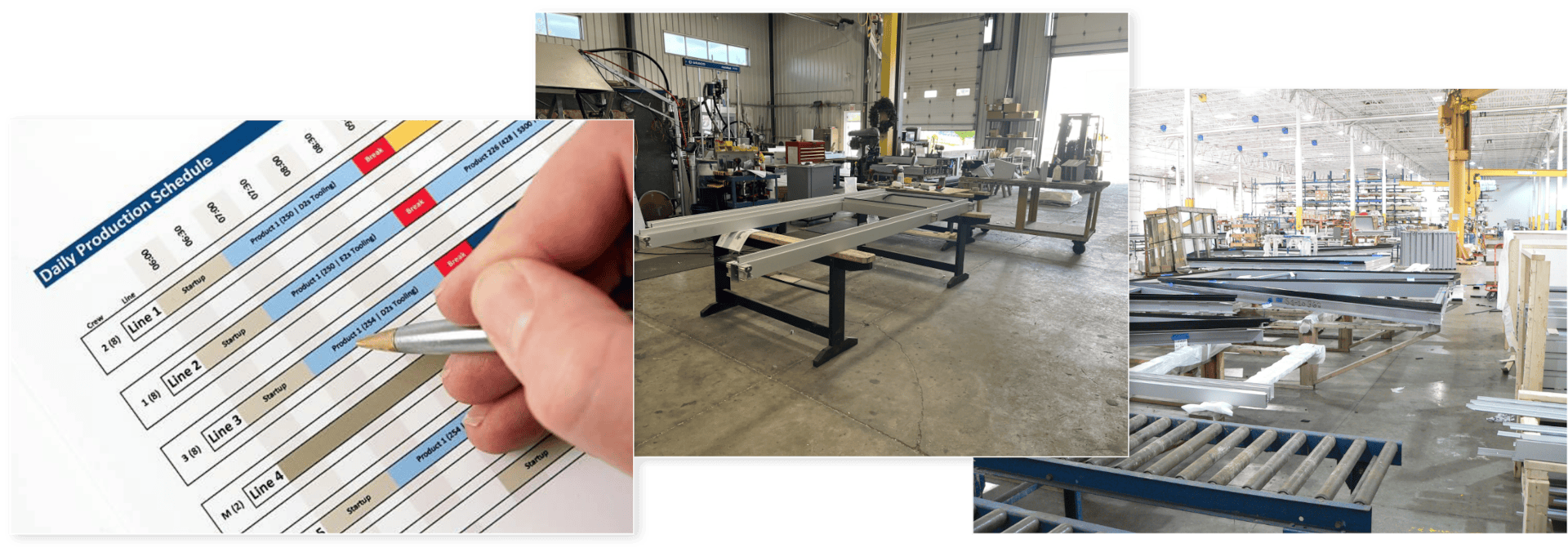

At SGI, we use detailed scheduling tools to manage product flow to the construction site

With BIM software, we seamlessly download cut lists directly to the saw and cnc machines, minimizing errors. Each cut is accompanied by barcode and ID marking labels for precise assembly and positioning. Our 5-Axis CNC machine preloads a machining sequence based on the barcode, eliminating manual programming. Quality control is integrated into every step of our manufacturing process, including final inspection, ensuring proper frame preparation and assembly. When possible, we preglaze and unitize frames, ensuring thorough cleaning before shipment to the job site.